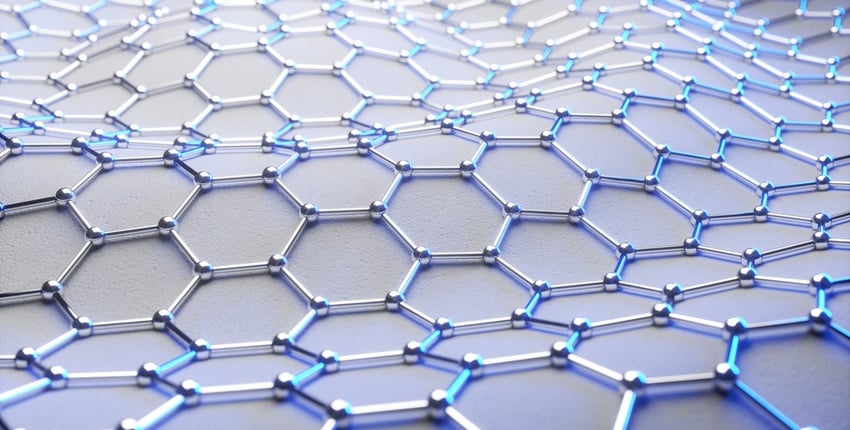

4 Ways Graphite Transforms Aerospace Engineering

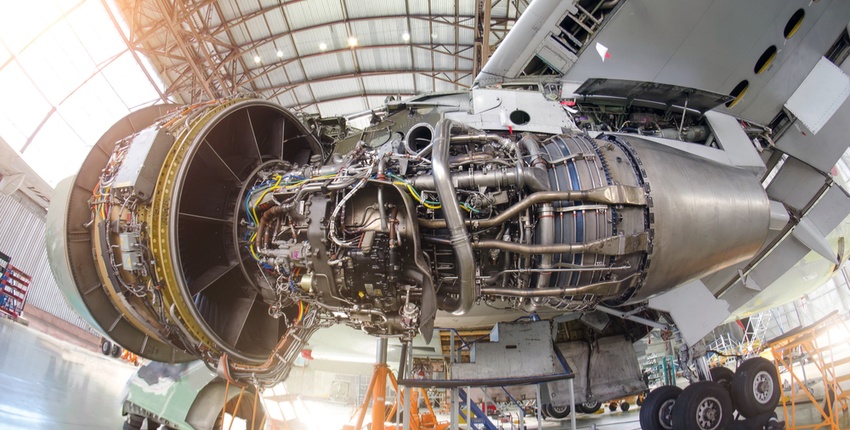

The aerospace industry leaves no margin for error, demanding materials that can withstand high altitudes, high speeds, and extreme temperatures upwards of 1,000 degrees to meet the strict safety requirements of the industry.