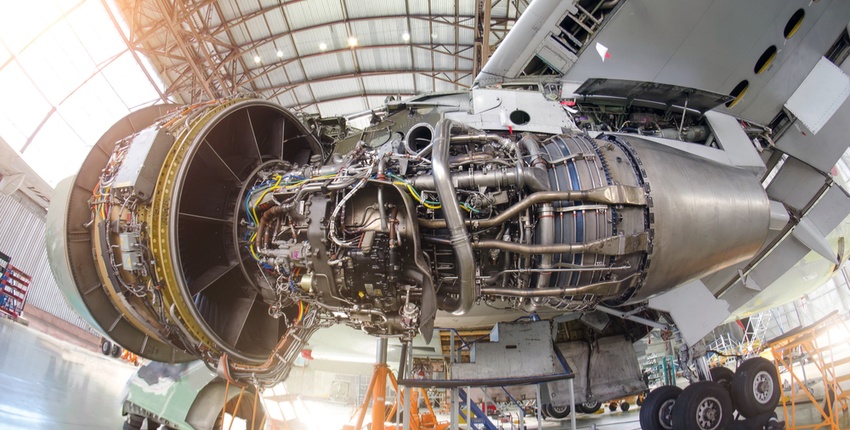

As engineers develop designs that push the boundaries of what’s possible, they search for new materials, or adaptations of materials, that can withstand increasingly extreme environments. Many new designs need materials that can endure extreme temperatures for long stretches of time, like seals and bearings that go into ovens, rockets, and turbines that can see temperatures above 1000°F. These temperatures wreak havoc on most traditional materials, rendering them expensive to replace or dangerous to operate.